1.special printing treatment 2.solid-liquid separation 3.long working life 4.save labour and enviromental cost 5.CE,ISO9000

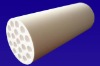

Ceramic membrane is a porous fine ceramic filter which is sintered from Alumina, Titania or Zirconia under ultra high temperature.

Ceramic membrane normally has an asymmetrical structure with porous support active membrane layer.

The macro porous support ensures the mechanical resistance while the active layer functions separation ranging from Microfiltration, Ultrafilatration and even Nanofiltration (from 10μm down to 1KD).

The advantage of special priniting treatment by ceramic membrane:

1.Surfactant and NaOH can be used again.2.Treating without flocculant or neutralizer, less contaminant.

3.Lowest energy cost because optimization of membrane and system design.4.Long work life for membrane filter5. Membrane layer is more abrasive compared with TiO2 and polymer membranes.6.Membranes is easy to be regenerated by normal chemicals like NaOH or HNO3.7. Reliable operation with PLC control.8.Easy maintenance which will save much labour cost.

inorganic Ceramic membrane Special printing treatment