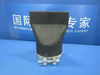

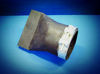

Rubber Check valve: 1.Quiet Operation 2.Zero maintenance 3.Design prevents backflow 4.Will seal around solids The best quality Rubber Check Valve: 1.Quiet operation2.Zero maintenance3.Design prevents backflow4.Will seal around solids Product Introduction:

Rubber Check valve is custom made and is intended for specific applications.It is designed to respond to criteria unique to its purpose,such as line pressure,backflow pressures,and chemical compatibility.

Should the conditions be altered or changed significantly,it could affect the normal operation of the check valve. Rubber Check Valve operates based on differential pressure,When the line pressure(at the valve inlet)exceeds the backpressure(at the valve outlet),the valve opens and flow is created.When the backpressure exceeds or overcomes the line pressure,the bill of the Rubber check valve seals shut,thereby preventing any backflow from occurring.

Installation:

1.Ensure that pipelines have been depressurized prior to installation,removal,or servicing the Rubber check valve.For best performance,bills should bu installed as close to the vertical position as possible,In cases where clearance below the pipe outlet is minimal,the Duckbill should be rotated only enough as required to avoid contact with the ground.

1.Do not install against raised-face flanges(only to smooth-face flanges).Remove all burrs or sharp edges from the pipe flange faces and wipe clean of oil,grease,etc.Apply a thin coat of graphite or glycerine to the pipe flange face,This will ease installation and allow for easy removal at a later date.

2.Lift the Rubber Check valve into position and align the bolt holes of the pipe flange,Rubber check valve flange and the retaining ring.Ensure that the Rubber check Valve's bill is oriented in a vertical position.

3.After the Rubber Check Valve and retaining ring(where applicable) are in the correct position,push two bolts through to ensure alignment.After the proper alignment has been obtained,install the remaining nuts and bolts using washer at the split holes(if the Rubber check valve comes with retaining ring).

4.Use two wrenches when installing the Rubber Check Valve.Tighten all flange bolts in a criss-cross pattern similar to the one shown in Figure 2 to the maximum torque recommended in Figure 3.

5.Do not weld near the Rubber Check Valve

Main data:

Matching Pipeline Diameter | Valve Step (A) | Pipeline Touching (B) |

1/2'-3/4' | 15 | 15 |

1'-1-1/4' | 20 | 20 |

1-1/2-2-1/2 | 25 | 25 |

3' | 40 | 40 |

4' | 50 | 50 |

6' | 50 | 50 |

8' | 50 | 50 |

10' | 50 | 50 |

12'-14' | 100 | 100 |

16'-20' | 150 | 150 |

24'-36' | 200 | 200 |

42' | 250 | 250 |

48'-60' | 300 | 300 |

72' | 400 | 400 |

The best quality Rubber Check Valve