13Cr-L80 seamless tubes are used for oil well serving in resistant corrosive environment.

13Cr-L80 seamless tubes are used for oil well serving in resistant corrosive environment, which requires excellent quality of resistant corrosion and strength, also requires high precision of bend and size. We have successfully developed 13Cr-L80 seamless tube according to API specification in 2002, and the size of oil tube is φ88.9*6.45*9700,coupling blank pipe isφ102*12, casing-tubing isφ139.7*6.98, and another coupling blank pipe isφ155*13.

Ⅰ. Grade and size

Grade: 2Cr13 (U.S.A. grade: 13Cr) (strength grade : L80)

Size and quantity: Oil tube: φ88.9*6.45*9700,

Coupling blank pipe: φ108*12,

Casing-tubing: φ155*13,

Ⅱ. Specification and the core of specification.

API 5CT: switching to enterprise specification

1. Chemical composition (%)

C | Si | Mn | P | S | Cr | Ni | Cu |

0.15-0.22 | ≤1.00 | 0.25-1.00 | ≤0.02 | ≤0.01 | 12-14 | ≤0.5 | ≤0.25 |

2. Delivery condition: hot extrusion quenching and tempering.

3. Tolerance and diameter:

O.D.: +1%/-0.5%, W.T. tolerance: -12.5%, quantity tolerance: -6.5%/-3.5%

Size of tube: φ(nominal I.D. of finish product:3.18mm)*152mm length ,Straightness: ≤2mm/m.

4. Mechanical property:

σb≥655MPa σs:552-655MPa δ5≥15% HRC≤25

AKV/0°C: Three samples from one tube (each furnace should check one tube) are made impacting test. Three values should be satisfied the requirement as follows: one of the value can lower than requirement, but can`t lower than 2/3 of the following values: lengthways AK of oil tube and casing-tubing ≥14.85J, the size of sample is 10mm*5mm, transverse AK of coupling blank pipe≥12J, the size of sample is 10mm*7.5mm.

Ⅲ.Production condition

We have comprehensive and flexible production ability, and progress many innovation and technology exploring. The producing difficulties of this tube are the high purity, strict mechanical property and rigorous tolerance. But at the controlling tolerance side, we break through the traditional way and add many producing procedure, such as extrusion ingot and cold work for controlling diameter etc., which ensure the tolerance within the API standard and protocol of buyer. For quality guarantee, we utilized the advantage of importing heat treatment equipment adequately, and controlled the quality stably within the desire range.

Chemical composition and inclusion

13Cr adopted EF+VOD melting. The chemical composition is in table 2,

Table 2, Melt chemical composition

Furnace No. | C | Si | Mn | P | S | Cr | Ni | Cu | [O] | N | Note |

406V1-629 | 0.18 | 0.34 | 0.67 | 0.020 | 0.004 | 12.5 | 0.12 | 0.06 | 56 | 88 | 3.2*12 |

406V1-630 | 0.16 | 0.38 | 0.65 | 0.020 | 0.004 | 12.35 | 0.15 | 0.08 | 42 | 67 | 3.2*12 |

406V1-631 | 0.19 | 0.31 | 0.64 | 0.020 | 0.003 | 12.13 | 0.15 | 0.04 | 46 | 80 | 3.2*12 |

406V1-632 | 0.17 | 0.36 | 0.68 | 0.019 | 0.003 | 12.18 | 0.09 | 0.04 | 53 | 80 | 3.2*12 |

At the same time, we used the microscope to test inclusion, the result is following,

Table 3 inclusion

Furnace No. | A | B | C | D | |||||

Thick | Thin | Thick | Thin | Thick | Thin | Thick | Thin | ||

406V1-629 | 1# | 0 | 0.5 | 1 | 0.5 | 0 | 0 | 2 | 1.5 |

2# | 0 | 0.5 | 1 | 1 | 0 | 0 | 0.5 | 1 | |

406V1-630 | 1# | 0 | 0.5 | 1 | 1.5 | ||||

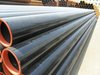

Seamless L80 13Cr pipe