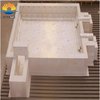

Fused Cast AZS are the most widely used materials both in glass contact and superstructure of glass fusion furnaces.

Glass fusion furnace used Casting AZS refractory Fused cast AZS for glass furnace

Physical and chemical index of glass furnace

Item | Behaviors | |||

AZS-33# ER 1681 | AZS-36# ER 1685 | AZS-41# ER 1711 | ||

Chemical Composition | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

SiO2 | ≤15.50 | ≤13.50 | ≤13.00 | |

Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

Bulk density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

Cold Crushing Strength Mpa | ≥300 | ≥300 | ≥300 | |

Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

Bubble Separation Ratio(1300°C×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

Anti-corrosion rate of glass liquid 1500°C×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

Apparent density (g/cm3) | PT(RN RC N) | ≥3.50 | ≥3.50 | ≥3.70 |

ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.70 | ≥3.90 | |

WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.8 | ≥4.00 | |

|

|

|

| |

Fused Casting AZS refractory for glass furnace