Sand production line: 1Reasonable allocation 2High-strength wearable material 3Well after sales service 4Long service life

2010 New Type Sand Production Line

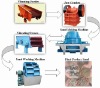

Application Our sand production line mainly consists of vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing machine, belt conveyor, electric control panel, etc, and capacity is 50-500T/H. Our sand production line is taking the leading role in the sand making industry. Sand production line can crush hard limestone, granite, basalt, river stone, etc, and widely used in hydropower, building material, highway, city construction, etc. Brief Introduction of Sand Production Line Large stone is transported to jaw crusher via vibrating feeder for primary crushing. Then crushed material is transported to sand making machine. Then the stones are screened out into several different types with a vibrating screen. Stone with satisfied size is transported to sand washing machine, then it will be final product, while overlarge stone is returned back to sand making machine for recrushing. Process of Sand Production LineThe raw material is transferred to jaw crusher for primary crushing by vibrating feeder, then the crushed materials are transferred to sand-making machine through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen. The materials with suitable size will be transferred to sand washing machine, after being washed, then clean final products will be discharged. The others with unsuitable size will be screened from vibrating screen, then will be transferred to the sand-making machine, this forms a closed circuit manifold cycles.Sizes of final products will be according to our customers' requirements. If it is the dry process, the classifier and deduster will be attached according to you requirement.Characteristics of Sand production lineCharacteristics of Sand production line: It is highly automatic. The efficiency is high, operation cost is low, crushing ratio is high, capacity is high, and pollution is very low. Size of final product is even, and with good shape, which complies with requirement for highway. In order to minimum occupation area, we try to make full use of space. Advanced electric control system makes the full line very smooth, reliable, and easy to maintenance.

Process of stone production line:Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopperfor primary crushing. After first crush, the material will transferred to impact crusher by beltconveyor for secondary crush; the crushed materials will then transferred to vibrating screen forseparating. After separating, the parts that can meet standard will be transferred away as finalproducts, while the other parts will be returned to impact crusher, thus forming a closed circuit.Size of final products can be combined and graded according to customer’s specific requirement.We can also equip dust catcher system to protect environment.

2010 New Type Sand Production Line