Detailed Product Description

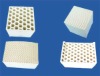

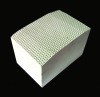

Cellular Ceramic Honeycomb Monolith For Heat Exchanger / Thermal Storage/Recovery Bed Ceramic Media, Rto

Description features:

Cellular Ceramic Honeycomb Monolith for Heat Exchanger / Thermal storage/recovery ceramic media, RTO Alias: Ceramic Honeycomb Heat Recovery Bed, heat exchange bed, Thermal storage& recovery ceramic media, heat exchange elements /media. Ceramic monoliths media evidently save energy in steel works and metallurgy industry, Regenerative thermal oxidizers (RTO). Honeycomb monolith is the key components of the style furnace, it is extensively used in many kinds of heater, sirocco furnace, heat treatment furnace, cracking column, roaster, melting furnace, balance heating stove and etc. This technology can save more than 40-70% of energy. It is also widely used in abatement of Volatile organic compounds (VOC), hazardous air pollutants (HAP), carbon monoxide (CO), nitrogen oxides (Nox), organic particulate matter (OPM), HC nytron, SO2, odors, and other air toxics in oil and chemical industry through a regenerative thermal oxidizer (RTO) device. Dust burning stove/ incinerator, power plant also needs ceramic honeycomb. An RTO device contains a ceramic heat exchanger bed which is used for the preheating and cooling of the waste gases before the gases enter and exit the combustion chamber, respectively. Advantages over ceramic saddles and balls: Compared with other ceramic media, such as saddles or ceramic balls, which have conventionally been used in RTOs. The advantages of the honeycomb monolith include a greater thermal efficiency and a lower pressure drop across the heat exchanger bed. The increase in thermal efficiency and lower pressure drop generally results in a smaller equipment design, lower capital costs and lower operating costs. Honeycomb ceramic provide a more efficient alternative for the following reasons: Cutting fan load for significant energy savings( low pressure drop owing to straight channels ), Less volume, thin wall thickness, faster in thermal exchange. High surface area means high conversion efficiency in converters occupying small volumes. Lighter weight, so less structural support is required. Thermal Oxidizers

Thermal oxidizers are ideal for areas with high fume concentrations and where emissions contain solvents, sulfides, silicones or heavy metals. Simplicity of design makes thermal oxidizers the best choice for many of today's pollution problems.

Key Benefits: Flexibility of horizontal or vertical design, Low maintenance issues.

Catalytic Oxidizers

Catalytic oxidizers are designed with low maintenance and fuel efficiency in mind. The oxidizers include an all welded stainless steel inner chamber, noble/precious metal monolith catalyst cells, industrial grade combustion system and controls.

Key Benefits: Optional heat recovery system and Low fuel consumption. Note:

The information contained in the tables below is believed to be accurate and reliable but is not to be construed as implying any warranty or guarantee of performance. Cell structure density ranges from 1 to 800 cells per square inch (CPSI). Material are typically available in cordierite, mullite and alumina etc on customer request. Cell shape in square, circle, hexagon, triangle etc. The following specification is just a small part of our available specification, just for your reference. We are also glad to accept customized product order.