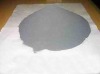

Microsilica Fume 1.Microsilica 85%-98% 2.Good Fluidity 3.Low permeability 4.Meets the requirements of ASTM C-1240

Microsilica Concrete

Microsilica is used in concrete.

When it is used in concrete, it acts as filler and as a cementitious

material. The small microsilica particles fill spaces between cement

particles and between the cement past matrix and aggregate particles.

Microsilica also combines with calcium hydroxide to form additional

calcium hydrate through the pozzolanic reaction. Both of these actions

result in a denser, stronger and less permeable material.

Microsilica: We have three factories in Shanxi, Yunnan and Qinghai

Province, China. Stable quality and reasonable price.

Application:

10% to 15% High strength structural columns

10% Flatwork

8% to 10%

High durability / Low permeability such as bridge decks or

parking structures

8% to 15% by weight of cement but as an addition not replacement

Microsilica has been used as an addition to concrete up to 15 percent by

weight of cement, although the normal proportion is 7 to 10 percent. With

an addition of 15 percent, the potential exists for very strong, brittle

concrete. It increases the water demand in a concrete mix; however, dosage

rates of less than 5 percent will not typically require a water reducer.

High replacement rates will require the use of a high range water reducer.

Function of adding Microsilica (Silica Fume):

• Increase durability

• Reduces concrete permeability

• Improves resistance to corrosion

• Shotcrete - lower rebound.

Microsilica Fume