1.Aluminum ceiling high quality. 2.factory price 3.good after-sale services 4.new box packing

Single Panel of Aluminium Series

Having purchased the high-quality aluminum alloy plate as the original material as well as the advanced data control bending technology, we can ensure that it won't change its style after dealing with the treatment. Meanwhile, the function is superb for resisting the outside force during the installation procedure. Surface coating originally from Mr. Len pvf2 coating as well as choose A Ke Su fluorine carbon (PVDF) coating material from united states, guarantee the well-distributed color on its surface, ultraviolet ray resistance, radiation-retarding, antioxidant, corrosion resistance.

Material and Construction

Aluminum plate curtain wall to its structure of which is made up of frontplate, reinforced rib, and angle is processed by high-intensity aluminum alloy material. The frontplate can be directly bent and stamped to the shape of angle, meanwhile, it is to be made by riveting on the frontplate flanging. The reinforced rib is jointed by the electrical welding bolt at the back of plate, so as to form the whole structure. Therefore, greatly reinforces the intensity and strengthen characters to aluminum single plate curtain wall, guaranteeing evenness and shock resistance ability. If it needs the sound insulation and heat preservation effects, it can be applied with sound insulation and heat.

Aluminum Single Plate of Structural Diagram

1. PVDF Fluorocarbon Resin Coating

2. Hanger

3. Strengthening Rib

4. Bolt

Superficial Treatment

Having been chromized firstly, then, the aluminum single plate is processed with fluorine-carbon spray coating. Pvdf (kanar500) of the fluorine carbon coating finish paint and the varnish is normally divided into 2nd coating, 3rd coating and 4rh coating. Fluorine carbon coating has outstanding characteristics of corrosion resistance and weathering resistance, resisting acid rain, salt fog and various kinds of air contaminants. Besides, is has good performance of thermal and cold endurance, meanwhile, it not only can resist strong ultraviolet ray, keeping unfading and chalking with long life-time application. Our factory chooses the world famous fluorine carbon coating material manufactured by ppg, dnt, akz0, and nippon, etc. In order to get different kinds of color. Customers can directly choose in accordance with the color catalogue or offer the color sample.

Structural Diagram of Single-Layer Aluminum Plate

1. Surface Painting or Protective Film

2. Primer or Graphics Layer

3. Primer

4. Aluminum Chromium Layer

5. Aluminum Plate / Aluminum Belt

6. Protective Layer / Protective Film

7. Back Painting

8. Aluminum Chromium Layer

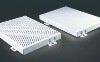

Material | Aluminium, Galvanised Steel,stainless steel etc. | |

Thickness | 0.4 - 1.2 mm | |

Color | White or coated with variable color poewed | |

pattern | Perforated make different patterns | |

Feature | ||

1) Surface smoothness and easy cleaning | ||

2) Flexible suspension system makes each ceiling tile easily installed and disassemble | ||

3) Easy to match lamps or other ceiling parts | ||

4) Surface color can be stable for 10 years by indoor use | ||

5)Light and handy Aluminum material,long service life,grace decorating | ||

1.Aluminum ceiling high quality. 2.factory price 3.good after-sale services 4.new box packing

5.Colour white or customized 6.Size: standard size (600X600) or customized 7.Thickness 0.4~1.2mm

8.Excellent surface flatness and smoothness

Aluminum Single Panel Ceiling