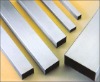

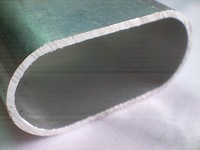

Large size and thin-wall aluminum extruded tubes and pipes, good ovality, high conductivity, good internal wall surface quality.

Welcome to Horizon Aluminum!

Horizon Aluminum is committed to supply high quality Aluminum products from China to the world.

Having engaged in aluminum business for over 5 years, we mainly supply the following products: aluminum extrusions-standards and custom, aluminum sheets and plates, foils and coils, and lots more.

Horizon Aluminum enjoys rich production capacities from its contracted mills, which are mainly located in the Bohai Sea Rim regions like Tianjin, Liaoning and Shandong. Horizon Aluminum has direct access to the management and technical teams of our mills to get first hand prices and production knowledge. The world first largest 100MN extrusion press in our mill is capable of extruding large size shapes, as well as 90MN, 80MN, 60MN, 55MN, 40MN and smaller ones. Our annual exporting volume is up to 3,000 metric tons of various extrusions, foil and plates.

Horizon Aluminum boasts its own extrusion die design and cutting capability, which is specialized in die design and cutting for sophisticated custom shapes and for extrusion presses over 40MN and above. We are very successful in R&D of large size dies for large OD tubes over 16 inches (OD406.4mm) up to 24 inches (OD609.6mm) We supply our products in most aluminum alloys and tempers: 2024, 3003, 5083, 6005, 6101, 6061, 6063, 6082, 7075, 5A06, 6060, to name a few.

Our core Aluminum products include:

*Common & marine alloy coil, sheet and plate

*Aluminum foil

*Seamless extruded and structural tubes

*Industrial and structural extrusions - Mill, anodized and painted finishes

* Comprehensive fabrication services

* Extensive dies available for service center standards.

* Large sized custom extrusion, extrusion die

Our products are widely used in the machine building, electrics & electronics, automotive, ship building, offshore platform, IT, telecom, defense industry, container making, high speed train and metro, construction, furniture and sporting equipment industries.

Our Sales Promise:

1. On-time delivery: your products will be delivered on time in sufficient quality and quantity without unreasonable delay.

2. After service: If any questions arise regarding product quality, we will respond and come with an acceptable solution within 48 hours or sooner.

3. Quality guarantee and money refund policy: In case of quality defect in our products we will either send new product for replacement at our own cost or compensate for metal scrap, 100% guaranteed.

In Horizon Aluminum mills, quality inspection is done at every stage in the manufacturing process right from the beginning. We build up our Total Quality Management (TQM) system, which ensures that the best products are delivered to our customers. At Horizon Aluminum, quality inspection is preformed and recorded in every process from billeting casting to final packaging. We monitor every critical point and make sure our product quality is traceable. The quality assurance procedures at Horizon Aluminum plants meet the most stringent requirements. All our mills are ISO9001:2000 certified, or OHSAS18000:1999 certified, which can be seen as evidence for the everlasting high quality of our products.

From years of business experience, Horizon Aluminum understands how important the packaging means to our products. We take care of not only the packaging materials, the bundles, the wood skids and blocks, but also the location of bundles inside containers, and one step further; we design our packaging in the way that it allows our customers unload bundles and packages easily from containers.

Sustainability is one of Horizon Aluminum's most important values; from production to packaging to shipping, we operate in a way to contribute to a green and clean planet.

Large section extrusion profiles have the following merits:

1. It can save further welding and joining work: In actual application of aluminum extrusion profiles, the parts are often required to be welded together to make a functional structure or parts. With larger and wider extrusion section, the welding process can be substantially reduced or saved, and some time the welding cost itself will be more expensive than the extrusion parts.

2. With whole piece extrusion, the extruded part will be more solid and stronger than welded parts. Arc welding seam may crack or leak but extruded part will not have such problem. It will remain intact and sound through out its service life.

3. Cost efficient: aluminum extrusion profile of large section and size will be more economic than welded parts of smaller size. The extrusion die is only one time investment and it will extrude as much as needed without further money input.

4. With high extrusion pressure of 100MN from this giant press, the extruded aluminum parts will be more compact in its inner micro structure, grain size will be more even and mechanical strength will be more consistent in its entire length. It will contribute to longer and stable condition of the extrusion products in its whole service life. Products made from such extrusion parts will be more durable in its application, tougher in structure and more reliable in its usage.

5. Matched with 30 meters long aging furnace, 18 meters high vertical quenching furnace and 2000T stretcher, our super large (100MN, 90MN and 80MN) extrusion press lines can make solution heat treatment to heat-treatable alloys and stress relieving treatment, to bring 2xxx, 6xxx and 7xxx alloys into T6511 tempers, which can guarantee the strength, hardness and machinability of the extrusion products.

Aluminum tube & pipe