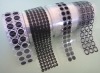

Automotive Vents ,snap-in vents Electronic Control Units Vents Protective Vents Acoustic Vents Adhesive Vents O-Ring

Micro-electro-acoustic dust gauze

Micro-electro-acoustic dust gauze preserve sound quality through acoustically transparent venting materials

Introduction of Micro-electro-acoustic dust gauzeMicro-electro-acoustic electro-acoustic dust gauze is a parts which used in electronic device to protect water and dust and sound transmission .Electro-acoustic vent materials have been widely used in computers, speaker phone, receiver, digital and communications equipment ,car speakers, multimedia speakers and other modern electronic products, extend the service life of such electronic products.Active lifestyles and harsh environments demand rugged electronics. This means devices such as mobile phones, computer equipment, and two-way radios must be able to tolerate some abuse. Even daily routines that expose devices to common elements — water, cleaning fluids, dust, and dirt — can damage sensitive acoustic and electrical components.Protective Vents for acoustics allow these devices to be dust-tight and, in some cases, water-tight. Along with protecting components from the weather, Protective Vents can withstand immersion in water to IP67. It resist a variety of common fluids such as soda, beer, and coffee. Often placed over ports in equipment, the vents are designed to preserve sound quality while creating a barrier from the elements for speakers, microphones, and alerts.minimal transmission loss due to the acoustically transparent materialsexcellent dust and liquid barrier for indoor and outdoor applicationsquick venting recovery after liquid immersionrobust adhesives that withstand challenging environments and adhere to different product surfacesstandard and custom designs readily availablelow profile that is ideal for devices with limited spaces

10. easy installation through either manual or automated process

11. dust, splash and immersion protection that meets a range of IP standards up to IP68

12. Micro-electro-acoustic vent dust gauze treated with fluorine coating non-woven, and nylon mesh, or ePTFE expanded polytetrafluoroethylene and the integrated of new polymer materials have super performance in anti-water ,dustproof and sound transaction . Use pressure-sensitive adhesive coating treated with fluorine-containing non-woven, or ePTFE expanded polytetrafluoroethylene and integrated new material after the forming die and improve the assembly efficiency, reduce production costs.Dust gauze structure and shape can customized according to customer requirements, with a new structure of the ear shape film , it is easy to peel off the adhesive protective paper.

13. Note of installation for Micro-electro-acoustic dust gauze

13.1 Assemble hole should be clean, flash and injection burrs should be removed

13..2 with adhesive in the back ,just take off the anti-stick paper when assemble .

13.3 Be careful of the vent dust gauze when assemble, do not damage the dust gauze

13.4 The vent cover operating temperature range between -40 °C ~ 85 °C, and if the operation temperature is excess the range temperature please take measures to protect it , because the material expansion and contraction of the big changes will affect the vents permeability.

Acoustic sound liner for venting